- +91-6301928064

The demand for high-performance shaped refractories has increased in recent years, primarily to changing steel-making trends. Al2O3-C refractories are frequently utilized in continuous steel casting. Because of their superior corrosion resistance and thermal shock resistance, these refractories are ideal for the production of slide plates. Al2O3-C refractories also have strong flexural and compressive strength, moderate thermal expansion, high thermal conductivity, low modulus of elasticity, and resistance to molten metal and slag.

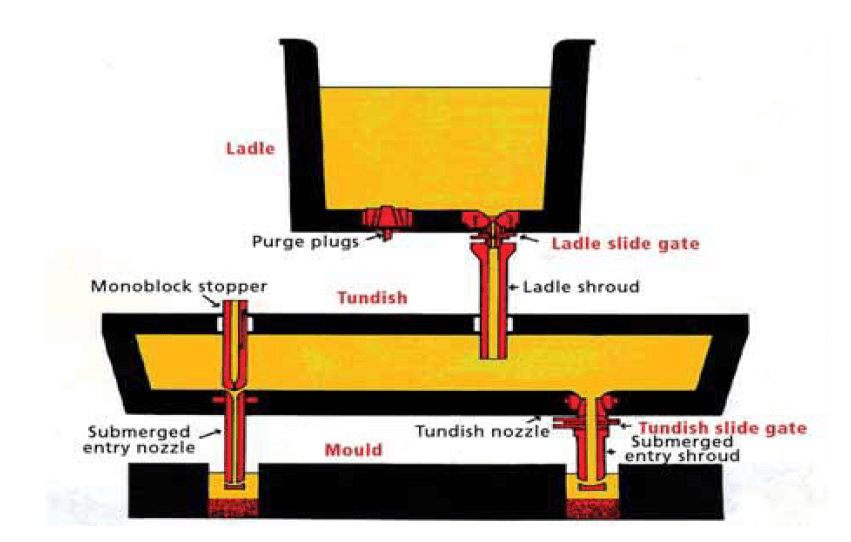

In the steelmaking process, one of the most significant refractories for continuous steel casting is the slide gate plate, which is used for precise flow control and safety. Slide gate plates, as indicated in the diagram below, regulate the flow of steel from the steel ladle to the tundish. Because they come into touch with hot liquid steel, the refractories used for slide plates should have higher hot strength qualities.

Slide gate plate refractories are utilized in ladles and tundishes where they are subjected to thermal stress and physical abrasion from molten metal and slag. As a result, the slide gate plate must be resistant to thermal shock as well as corrosion. The structure of slide gate plate refractories determines the capacity and cost of steel production. The slide gate plate can be manufactured of alumina/graphite or magnesia/graphite, depending on the steel production requirements. In recent years, alumina/carbon refractories have become increasingly popular in order to avoid fuming caused by pitch, which was previously utilized in the plate, and to improve durability and service environment. The downside of alumina/graphite is that it is eroded quickly by “Ca” treated steel and strong oxygen contacts. Basic materials have better corrosion resistance than neutral metals, and their corrosion resistance varies depending on the steel grade. However, due to their high thermal expansion coefficient, neutral metals have reduced thermal spalling resistance. When high-temperature fluids, such as molten metal, flow through the nozzle of a slide gate plate, a large temperature difference occurs between the inside and outer parts of the slide gate plate that are away from the nozzle hole, causing thermal shock to some of the materials that make up these parts. As a result, the gate plate device is made of refractory material with strong thermal shock resistance but low fineness.

The slide gate nozzle for receiving a melt of special steel, notably molten steel deoxidized with “Ca” alloy, is made of a zirconia-based material, which lacks stability in spalling resistance and so does not guarantee sufficient durability.

In steel casting operations, Al2O3-C refractories are commonly utilized. The so-called functional components, such as submerged entry nozzles, mono-block stoppers, and ladle shrouds, are the most basic members of this refractory product group, which are utilized in continuous steel casting.

As mention above slide gate plate refractories is one of the most important components in Steel Making process due to their ability to control the flow of steel from ladle to tundish. MPR Refractories Ltd. manufactures a wide selection of Slide Gate Plates, including the typical 1QC, 2QC, Chinese design, and Saflow Systems. We’ve also created slide plate systems with Zirconia Insert co-molded into Alumina Carbon to provide higher erosion resistance against aggressive steel grades over long casting sequences. This extends the life of the Slide Plate System.