- +91-6301928064

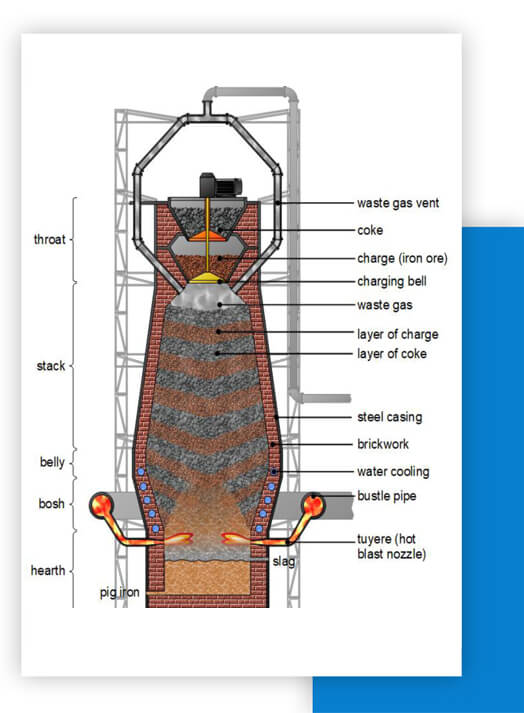

Iron Industry is dynamic operation module either you make good money or you lose drastically due to errors over Production Process, The most crucial point for an industrialist in this trade is achieve longer Blast furnace life due to two reasons one its time consuming exercise & second the cost involved is high.

Though the hearth remains the most critical zone for repair, the stack can always be re-profiled. robotic maintenance or manual installations by lifting platform are today are well established techniques used worldwide.

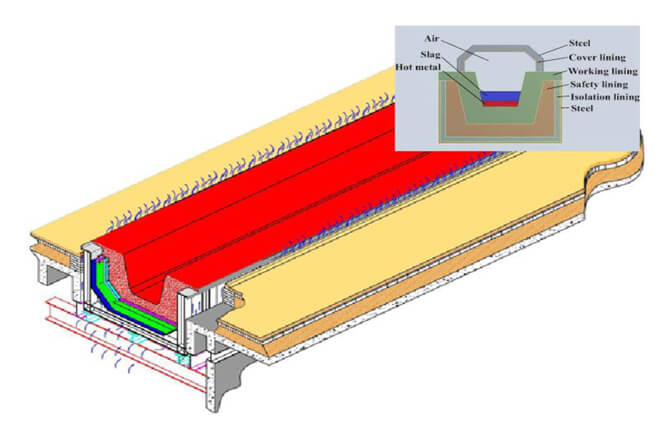

We support best with best Refractories for the Blast furnace in order to have better service life extension & related environmental/safety issues keeping in mind factor like cost reduction without compromising quality and help our clients with Value for money products & services. We Focus over Runner design, product architecture, along with accurate emphasis over application technology that contribute to desired performance of the Casthouse. We provides reliable high alumina -silicon carbide -carbon products for all working and safety linings of the runners keeping in mind long campaign service life, Low and ultra-low cement castable, Brown fused alumina and silicon carbide based, High erosion resistant, Iron and slag resistant, Thermal cycling/thermal shock resistant, Low cracking behavior & Pitch-free and no toxic emission with Long service life, No cracks formation use of Oxidation resistant, High mechanical properties, Casted on site in precast blocks, Designed for zoned lining with Pitch-free and no toxic emission for Safety Linings.

Controlled Casting rate, corrosionresistance and balancing the Taphole wear and the renewal of the “mushroom” are all aspects creating synergy between the user’s demand and the producer’s capability.

Special attention is paid to the product design and manufacturing to ensure stable furnace operation and hearth walls protection.

We Supply best in class clay that can support you with Daily iron production up to 10,000 t/d,Short intermediate tapping time, 18 min ,Prolonged continuous operation on the same taphole, more than 18 days & easy drilling at the scheduled time.

All this along with Long and stable taphole length, Low specific consumption,Longercasting duration i.e over 200 mi ,Lowest emission &Controlled casting rate.