MPR Refractories Services

We Provide Refractories Solutions

35+

Year's Of Experience

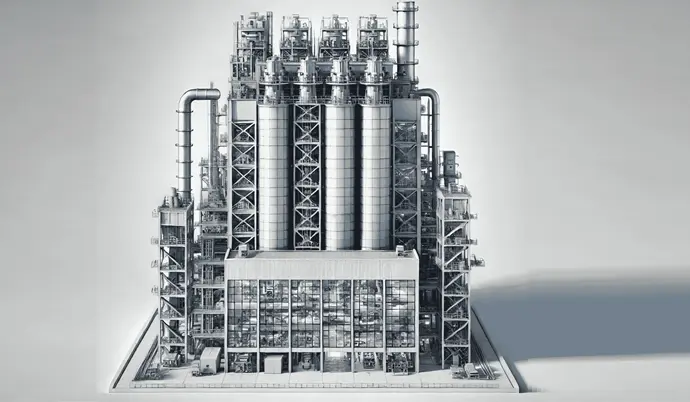

About MPR Refractories

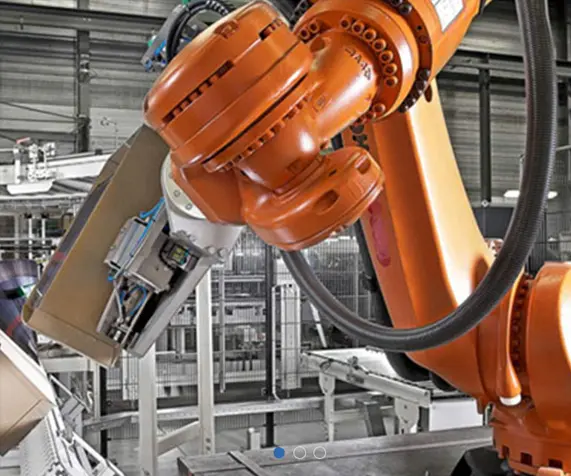

Industry-Leading Refractory Solutions

With over 35 years of experience, MPR Refractories stands at the forefront of innovation and reliability in the industrial sector. Our modernized facilities, upgraded in 1994 and 2008, house cutting-edge technology to meet the most demanding needs:

- Closed circuit crushing grinding system

- Intense mixers

- PLC controlled high capacity presses

- Continuous oil fired tunnel kilns of (+) 1700°C

- High temperature furnaces for special products

At MPR Refractories, we are dedicated to delivering unparalleled quality and efficiency to support your industrial operations.

MPR Refractories in Numbers

Why MPR Refractories

We Provide the International Standard Quality

At MPR Refractories, we combine decades of expertise with cutting-edge production facilities to provide world-class refractory solutions.

The Best Quality of Services

ISO 9001:2015 Certified for quality excellence

Creative Innovations From Production Industry

Modernised facilities with continuous upgrades (1994 & 2008)

Customer Service

Emphasis on innovation, customer satisfaction, and precision

Testimonial

Clients Words

Rewards & Recognition

Recognised for excellence and innovation, MPR Refractories is a trusted leader in delivering high-quality refractory solutions to industries worldwide.

Media Center

Gallery

Latest Blog

Latest Posts & Articles

16 Nov

How to choose the best refractory material?

In order to be a successful plant operator (Steel/Ceramic/Cement/Glass & other allied products), you need to find the best refractory.

27 Oct

Enhance the Refractory’s Performance by Using the Proper Dry Out Procedure

After refractory installation, a refractory drying out process is required before operations can initiate.

15 Oct

The Consumption & Production of Global Steel in 2020

The newly released “World Steel Statistics for 2021” by the World Steel Association shows that the world’s crude.